- HOME

- RECORDING PAPER

- Features and Specification

Pressure measurement film Prescale

Prescale can measure pressure and visualize pressure range.

When pressure is applied, the micro capsules are broken and the color-forming material reacts with the color-developing material. Red patches appear on the film.

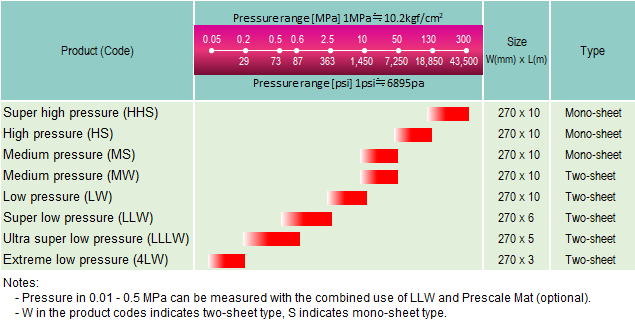

Select appropriate Prescale.

Working Principle

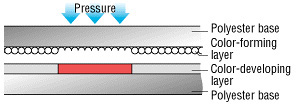

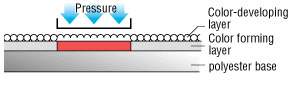

Structure

Mono-sheet type: The color-developing material is coated on a polyester base, with the micro-encapsulated color-forming material layered on top.

Two-sheet type: One film is coated with the micro-encapsulated color-forming material and the other film is coated with the color-developing material. Use two films facing the coated sides each other.

Two-sheet type

Mono-sheet type

Properties

| Two-sheet type | Mono-sheet type | |

|---|---|---|

| Accuracy | ±10% or less(when measured with densitometer at 23°C, 65%RH) | |

| Recommended temperature | 20°C~35°C | |

| Recommended humidity | 35%RH~80%RH | |

EXAMPLES

Engine gasket surface seal surface pressure measurement, flange surface pressure analysis, tire ground contact surface/ground contact pressure analysis, roll contact pressure measurement, etc.

Airbag load measurement

Air-conditioner seal surface pressure measurement

Clutch joint pressure measurement

Flange surface pressure measurement

Die pressure test

Long jump balk line pressure analysis

Engine cylinder gasket surface pressure measurement

Pressure distribution and pressure value measurement represents a significant problem when tightening engine cylinder gaskets. However, by inserting "Prescale" between the cylinder block, and gasket and cylinder head, measurement is possible simply by tightening. The great thing about "Prescale" is that its adoption for JIS D3150 "Cylinder head gaskets for automobile engines" performance testing has also been demonstrated.

Seal flange surface pressure analysis

Flange surfaces must be tightened securely and with an appropriate amount of pressure applied in order to prevent oil leaks. When measuring with sensors and so on, it is difficult to measure pressure distribution over the entire area. However, by inserting "Prescale" between the flanges, it is only necessary to tighten. Pressure distribution can then be read accurately by attaching "Prescale" to a reading device.

Tire ground contact surface / ground contact pressure analysis

The tire is a vital part of automobiles required to "drive", "turn", and "stop" both safely and accurately. When analyzing the ground contact surface where the tire makes contact, the ground surface pressure can be distributed and analyzed easily and accurately without having to route sensor cables, etc. This method involves simply inserting "Prescale" between the ground contact surface (asphalt, etc.) and the tire. By then attaching "Prescale" to a reading device, if using the FPD-901 Series, the ground contact distribution can be obtained by visual observation and with numerical values.

Roll contact pressure measurement

In the past, the tension applied when rolling steel sheet was determined based on a combination of past experience and intuition. It was common, however, for defects to occur such as part of the roll bulging, and so there was nothing for it but to take a repetitive cut-and-try approach until the appropriate tension was reached. Rolling the steel sheet together with "Prescale", however, allows the rolling pressure to be measured accurately, allowing tension adjustments to be standardized, and contributing to reduced costs.